Understanding Low Volume Injection Molding For Small Batch Plastic Parts Production

Low volume injection molding is a manufacturing method that has become increasingly popular recently, and this process is ideal for producing consistent quality small quantities of plastic parts. This blog post will explore the basics of low volume injection molding, including its benefits, how it works, its advantages, applications, and factors to consider when choosing this manufacturing method.

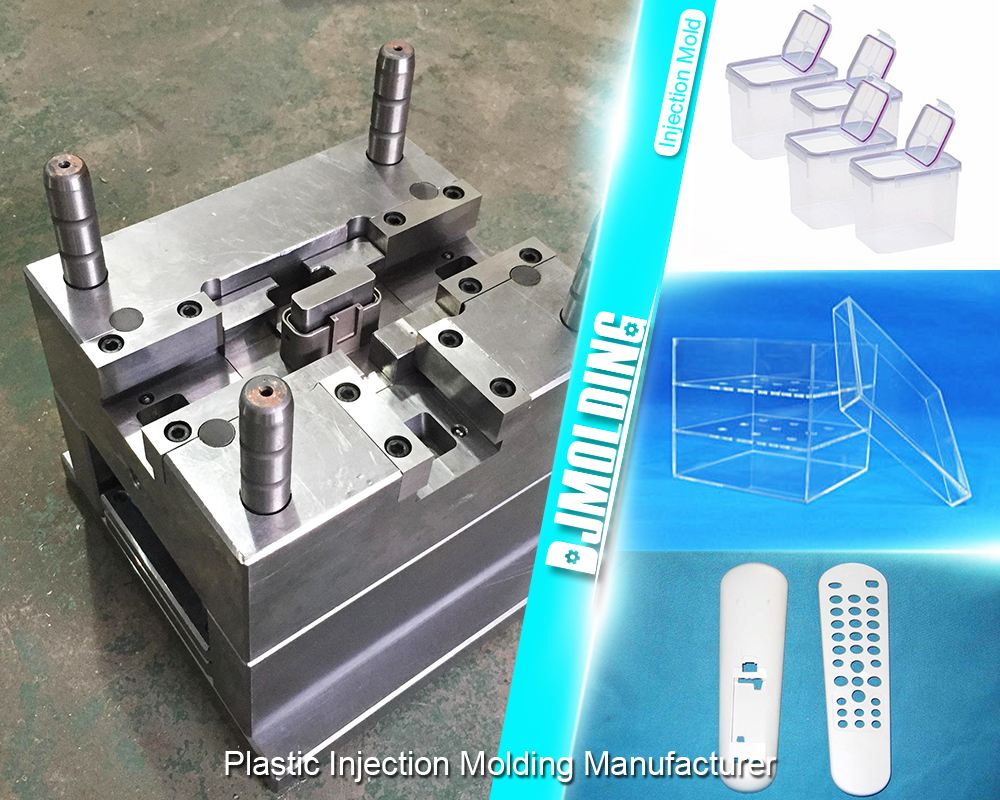

What is Low Volume Injection Molding?

Definition and Explanation

Low volume injection molding is a manufacturing process that involves the creation of custom tooling to produce small quantities of plastic parts with consistent quality. It is a cost-effective way to make small batches of parts for different industries.

Benefits of Low Volume Injection Molding

- Reduced tooling costs

- Short lead time

- Quick iterations

- Low risk for product design changes

- Flexible production capabilities

- Lower cost for prototyping

- Reduced waste material

How Does Low Volume Injection Molding Work?

Low volume injection molding is a manufacturing process that allows for producing small quantities of plastic parts with consistent quality. The process involves the creation of custom tooling, injection molding of plastic material into the mold, and quality control measures. Let’s explore each step in detail:

Tooling Creation

- Designers create custom tooling to produce a mold capable of producing consistent quality small quantities of plastic parts.

- Typically, manufacturers make the tooling from steel or aluminum, designing it to withstand the high pressures and temperatures of the injection molding process.

- The design of the mold is crucial for ensuring the quality of the final product, and it must consider factors such as geometry, material flow, and cooling time.

Injection Molding Process

- The plastic material is melted and injected into the mold under high pressure.

- The mold is then cooled to allow the plastic to solidify and take the shape of the mold.

- Once the plastic hardens, someone opens the mold and removes the part.

The process is repeated for each element until we achieve the desired quantity. Quality Control

- Quality control measures are implemented throughout manufacturing to ensure the parts meet the required specifications.

- Inspectors examine the tooling to ensure it is in good condition and capable of producing high-quality parts.

- Operators monitor the quality of the materials used in the injection molding process to ensure consistency.

- Inspectors examine finished pieces to ensure they meet the required dimensional and visual specifications.

Advantages of Low Volume Injection Molding

Cost-Effective

- Low volume injection molding is a cost-effective way to produce small quantities of plastic parts. The tooling costs are significantly lower than other manufacturing methods, and the production process is efficient.

Fast Turnaround Time

- The lead time for low volume injection molding is much shorter than other manufacturing methods. Manufacturers create the tooling quickly and execute the production process efficiently, resulting in faster turnaround times.

Flexibility in Design

- Low volume injection molding offers flexibility in design, allowing for quick iterations and product changes without incurring significant costs.

Consistent Quality

- The custom tooling used in low volume injection molding produces consistent quality parts, ensuring that each piece is identical to the previous one.

Eco-Friendly

- Low volume injection molding produces less waste material, making it an eco-friendly manufacturing method.

Applications of Low Volume Injection Molding

Low volume injection molding is a versatile manufacturing process that finds applications across various industries. Here are some of the typical applications of this process:

Medical Devices

- In the medical industry, manufacturers require the quick and consistent production of small batches of custom parts.

- Low volume injection molding is a cost-effective way of making medical devices such as surgical instruments, implants, and drug delivery devices.

Manufacturers can create these parts highly, ensuring they meet the industry’s strict regulatory requirements. Aerospace

- In the aerospace industry, manufacturers require the production of custom parts in small quantities.

- Low volume injection molding can produce parts such as brackets, knobs, and handles for aircraft interiors.

- The process offers a high design flexibility, essential in the aerospace industry, where functions must meet specific weight, strength, and durability requirements.

Electronics

- Manufacturers require the quick and cost-effective production of small quantities of custom parts in the electronics industry.

- Low volume injection molding can produce parts such as electronic device housings, connectors, and switches.

- This process offers high precision and repeatability, essential in the electronics industry, where parts must fit perfectly.

Consumer Goods

- Low volume injection molding produces small batches of custom plastic parts for consumer goods such as toys, sporting equipment, and household appliances.

- This method offers a cost-effective way of creating pieces with complex shapes and designs and with consistent quality.

- It also allows for producing unique or custom features unavailable in the mass market.

Factors to Consider in Low Volume Injection Molding

Low volume injection molding offers many advantages, but there are also important factors to consider when choosing this manufacturing method. Here are some of the critical factors to keep in mind:

Material Selection

- Choosing the suitable material is crucial to achieving the desired outcome in low volume injection molding.

- Factors to consider the material’s properties include strength, flexibility, durability, and compatibility with the injection molding process.

- Material selection can affect the final cost and quality of the parts produced.

Design Optimization

- Design optimization is vital to achieving the best possible low-volume injection molding results.

- Designing efficient and cost-effective parts that meet functional requirements is the goal.

- Design optimization can minimize tooling costs and reduce production time.

Tooling Costs

- Low volume injection molding requires businesses to invest in custom tooling, which can result in a significant upfront cost.

- However, the cost per part decreases as the production volume increases.

Businesses can minimize tooling costs by choosing the right production volume and optimizing the design. Production Volume

- Low volume injection molding is ideal for producing small batches of parts quickly and cost-effectively.

- However, it is vital to consider the production volume when choosing this manufacturing method.

- As the production volume increases, other manufacturing methods, such as high volume injection molding or other processes, may become more cost-effective.

Conclusion

Low volume injection molding is a cost-effective way of producing small quantities of plastic parts with consistent quality. This process offers many advantages over other manufacturing methods, including fast turnaround time, flexibility in design, and consistent quality. By considering factors such as material selection, design optimization, tooling costs, and production volume, businesses can decide whether low volume injection molding is the right choice for their manufacturing needs. With the right approach, low volume injection molding can effectively bring new products to market quickly and cost-effectively.

For more about understanding low volume injection molding for small batch plastic parts production,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-injection-molding/ for more info.

Article Original From: https://www.djmolding.com/understanding-low-volume-injection-molding-for-small-batch-plastic-parts-production/