Custom Automotive Plastic Components Injection Molding Manufacturing Process

This blog post will provide a comprehensive guide to automotive plastic components injection molding, covering everything from the basics of injection molding to the benefits of plastic parts in the automotive industry, the types of plastic used in injection molding, the injection molding process, challenges and best practices for successful injection molding.

Manufacturers widely use injection molding as a process in which they inject molten plastic into a mold, which cools and solidifies into the desired shape. The process is vital in the automotive industry due to the numerous benefits of using plastic components, such as increased durability and reduced weight. This guide will explore the different types of plastic used in injection molding for automotive parts, the process, the benefits and challenges associated with injection molding, and best practices for successful injection molding.

Types of Plastics Used in Injection Molding for Automotive Components

Manufacturers widely utilize thermoplastics in injection molding for automotive components because they can melt and re-melt them repeatedly, making them ideal for the process. Below are some of the commonly used thermoplastics in the automotive industry:

- Polypropylene (PP): This is a lightweight, versatile, and cost-effective thermoplastic used in the automotive industry for various components such as bumpers, instrument panels, and interior trim.

- Acrylonitrile Butadiene Styrene (ABS): This is a challenging and impact-resistant thermoplastic commonly used in the automotive industry for dashboard components, wheel covers, and exterior trim components.

- Polyamide (PA): Also known as Nylon, polyamide is a solid and durable thermoplastic used in the automotive industry for components such as fuel lines, engine covers, and air intake manifolds.

- Polycarbonate (PC): This is a transparent and lightweight thermoplastic with high impact resistance used in the automotive industry for components such as headlamp lenses, instrument panels, and sunroofs.

- Polyoxymethylene (POM): Also known as Acetal, POM is a high-strength and low-friction thermoplastic used in the automotive industry for components such as gears, fuel systems, and door handles.

- Polyethylene (PE): This is a lightweight, flexible, and cost-effective thermoplastic used in the automotive industry for components such as fuel tanks, wire and cable insulation, and underbody shields.

- Thermoplastic Elastomers (TPE): These are rubber-like thermoplastics with excellent flexibility and durability used in the automotive industry for components such as weather seals, gaskets, and hoses.

The Injection Molding Process for Automotive Plastic Components

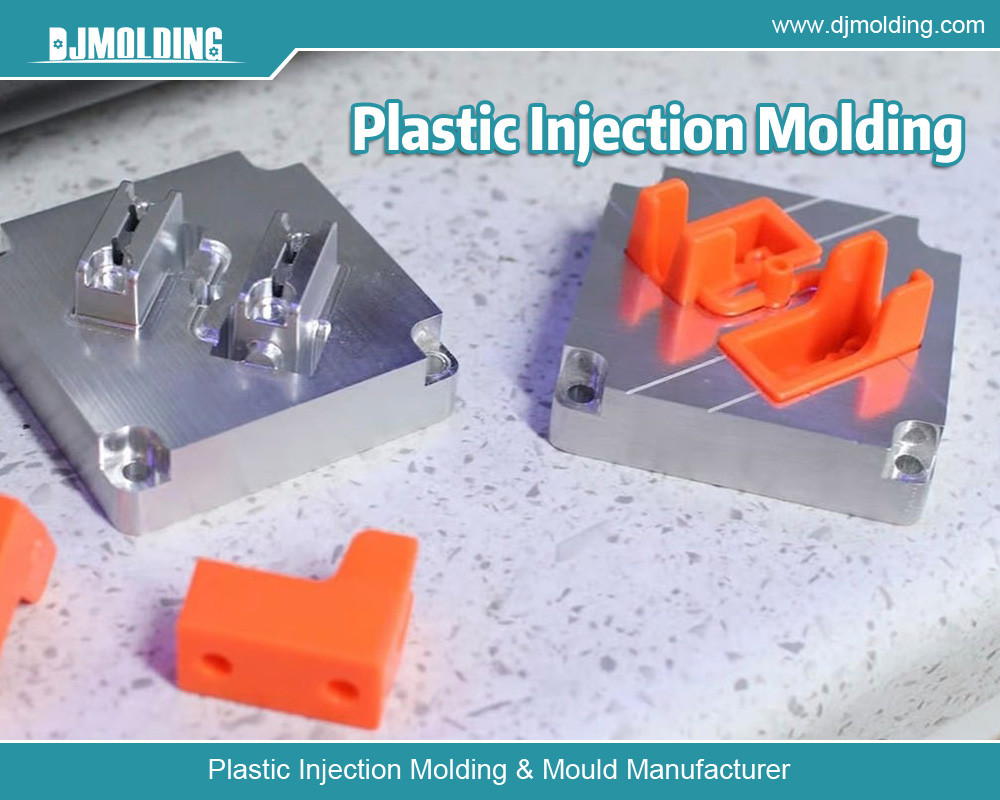

Injection molding is a widely used manufacturing process for producing plastic parts, including those used in the automotive industry. The process involves injecting molten plastic into a mold, which is then cooled and solidified to form the desired part. Here are some of the key steps involved in the injection molding process for automotive plastic components:

- Mold design and construction: We design and construct the mold to produce the part according to its specifications. The mold is typically made of steel or aluminum and consists of two halves joined together.

- Injection molding machine: The machine is responsible for heating and injecting the plastic material into the mold. You must appropriately calibrate and maintain the device to ensure the quality and consistency of the final product.

- Injection molding process steps: The process consists of four main steps: clamping, injection, cooling, and ejection. The mold is closed and held firmly in place during the clamping step. Next, we inject the plastic material into the mold under high pressure. We then cool the mold to solidify the plastic and eject the final part.

- Post-molding processing and inspection: Once we eject the part from the mold, it may require additional processing, such as trimming or finishing. We must also inspect the piece to ensure it meets the required specifications.

The injection molding process can be complex and requires careful attention to detail to ensure the quality of the final product. The injection molding machine plays a critical role in the process, and proper calibration and maintenance are essential for successful injection molding.

Benefits and Challenges of Injection Molding for Automotive Plastic Components

Due to its numerous benefits, injection molding has become a popular manufacturing process for automotive plastic components. Some of the benefits of injection molding include:

- Cost-effectiveness: Injection molding can be economical for producing high volumes of automotive plastic components. Once we create the mold, the cost per part decreases significantly, making it an attractive option for mass production.

- High precision and consistency: Injection molding increases accuracy and consistency in producing automotive plastic components. The process is highly automated, which minimizes the possibility of human error.

- Variety of shapes and sizes: Injection molding allows for producing a wide range of shapes and sizes of automotive plastic components. The manufacturing process is ideal for creating complex and intricate parts that would be difficult or impossible to produce using other methods.

- Enhanced strength and durability: Injection molding makes more robust and durable materials than other manufacturing processes. Using this method, the plastic components of automobiles become more durable and better equipped to handle the wear and tear of everyday use.

- Lightweight: Injection molding allows for the creation of lightweight automotive plastic components, which can help to improve fuel efficiency and reduce overall vehicle weight.

- High production volume: Injection molding is a high-volume manufacturing process that can produce large quantities of automotive plastic components quickly and efficiently.

- Despite these benefits, injection molding for automotive plastic components has some associated challenges. These challenges include:

- Design challenges: We must carefully consider the design of the mold and the part to ensure that the final product meets the required specifications.

- Material selection challenges: The suitable material for the automotive plastic component is crucial to its performance and durability.

- Manufacturing challenges: The injection molding process can be complex, and several factors can affect the quality of the final product. These include machine calibration, temperature control, and mold maintenance.

Best Practices for Successful Injection Molding

Injection molding is a complex process requiring careful attention to many factors to achieve a successful outcome. To ensure the best results, following best practices for each process step is essential. Here are some important best practices for successful injection molding of automotive plastic components:

- Proper Mold Design and Construction: The mold’s design and construction can significantly impact the quality and consistency of the final product. It is vital to work with experienced mold designers and manufacturers who can ensure that the mold is appropriately designed and constructed for the specific application.

- Material Selection and Preparation: The selection and preparation of the material used in the injection molding process is critical to achieving the desired properties and characteristics in the final product. It is essential to carefully evaluate different materials and select the best suited for the specific application. We must also appropriately prepare the material for injection molding, which may involve drying, blending, or other treatments.

- Injection Molding Machine Calibration and Maintenance: We must adequately calibrate and maintain the injection molding machine to ensure consistent and accurate operation. To ensure the device is running at its best, it’s important to regularly calibrate the temperature, pressure, and other settings and perform routine maintenance and repairs.

- Monitoring and Control: During the injection molding process, it is vital to monitor and control key variables such as temperature, pressure, and flow rate to ensure that the process proceeds as planned. One may need to utilize sensors, automated controls, or manual adjustments to maintain the desired conditions.

- Post-Molding Processing and Inspection: Once the injection molding process is complete, the final product must be properly processed and inspected to ensure that it meets the required specifications. To ensure quality, performing tasks such as trimming, polishing, and other finishing operations may be necessary. The operator should conduct a thorough inspection to detect any defects or inconsistencies that require attention.

By following these best practices, manufacturers can help ensure the quality and consistency of their injection-molded automotive plastic components while minimizing the risk of defects or other issues that can impact performance and reliability.

CONCLUSION

In conclusion, automotive plastic components injection molding is a critical process in the automotive industry that offers numerous benefits, including cost-effectiveness, precision, strength, and durability. By following best practices and understanding the challenges associated with the process, manufacturers can ensure the success of their injection molding operations and continue to produce high-quality automotive components for years to come. With the ongoing advancements in plastic technology, the future of automotive plastic components injection molding looks bright.

For more about custom automotive plastic components injection molding manufacturing process,you can pay a visit to Djmolding at https://www.djmolding.com/automotive-plastic-components-injection-molding-manufacturer-revolutionizing-automotive-manufacturing/ for more info.

Article Original From: https://www.djmolding.com/custom-automotive-plastic-components-injection-molding-manufacturing-process/